HOME / QUALITY

Quality Control with ISO 13485

THY Precision is committed to maintaining the highest standards of quality in all aspects of our production process. As a result, we have implemented strict protocols and procedures for Quality Management System (QMS) at every stage of production. Our dedication to quality is reflected in our ISO 13485 certification for medical devices. All of our products are produced in accordance with ISO 13485 standards, ensuring that our customers receive the highest quality products.

Monitoring System for Quality Assurance

Certificates ISO 13485 & ISO 9001

THY Precision’s quality control certified by not only ISO 9001 but also ISO 13485 has a standard and complete management system for any precision plastic injection products, both certifications demonstrate our capability to deliver high-quality production process and output.

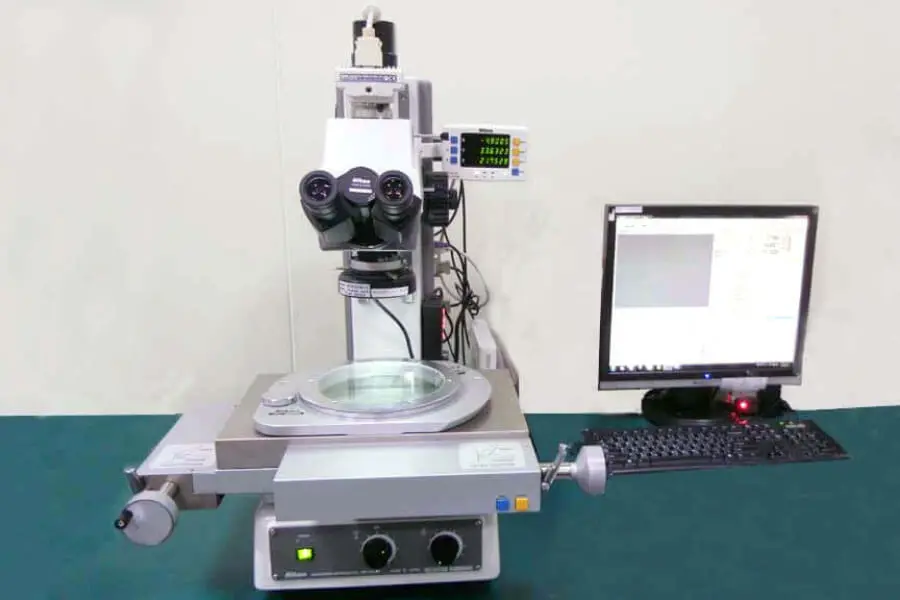

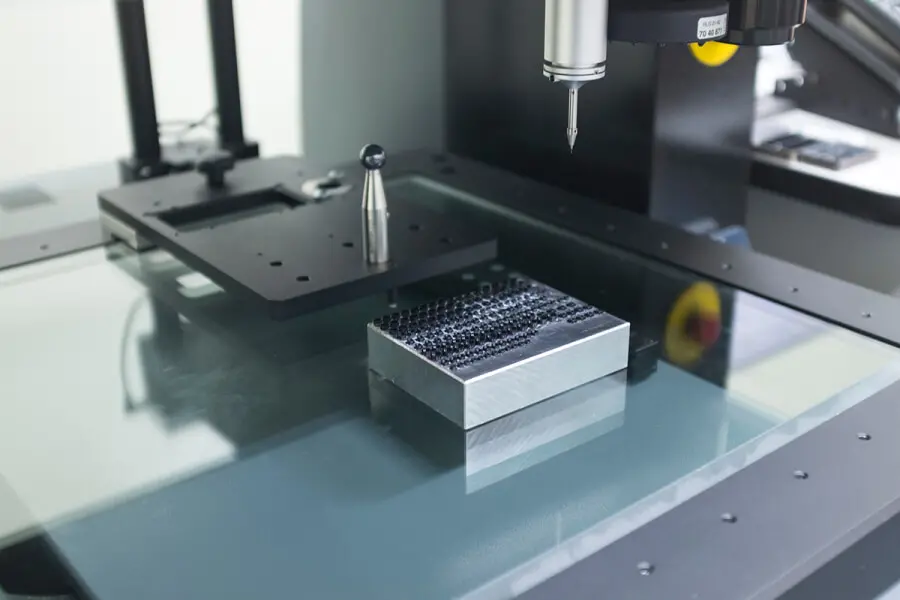

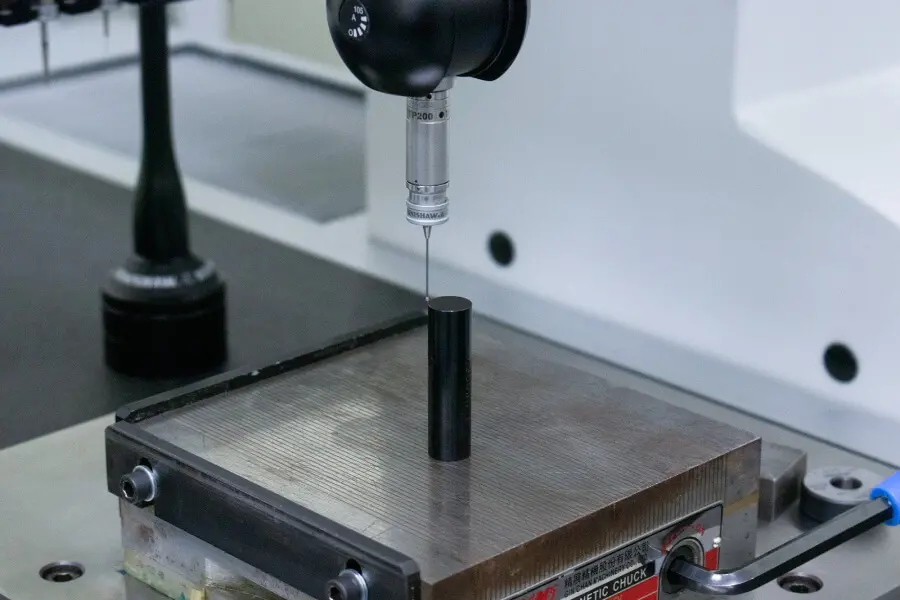

Inspection Equipment

In order to provide the best quality products to our clients, we have invested in and equipped with the latest and highest precision inspection equipment, allowing to provide much better quality more than the standard micro injection requirement. With up-to-date technology, our engineering team develop or find the solution by lowest time consumption, and this greatly improves efficiency to help our customers get ahead of the game.