HOME / Custom Plastic Moldings

Custom Plastic Moldings

Precision Solutions for Your Manufacturing Needs

In the world of manufacturing, precision and customization are of paramount importance, especially when it comes to plastic moldings. Custom plastic moldings offer tailored solutions for a wide range of industries, ensuring that every product meets specific requirements with exacting precision. If you’re in need of high-quality custom plastic moldings, we will guide you through the benefits and explain why choosing a professional manufacturer is your best choice.

The Key Advantages of Custom Plastic Moldings

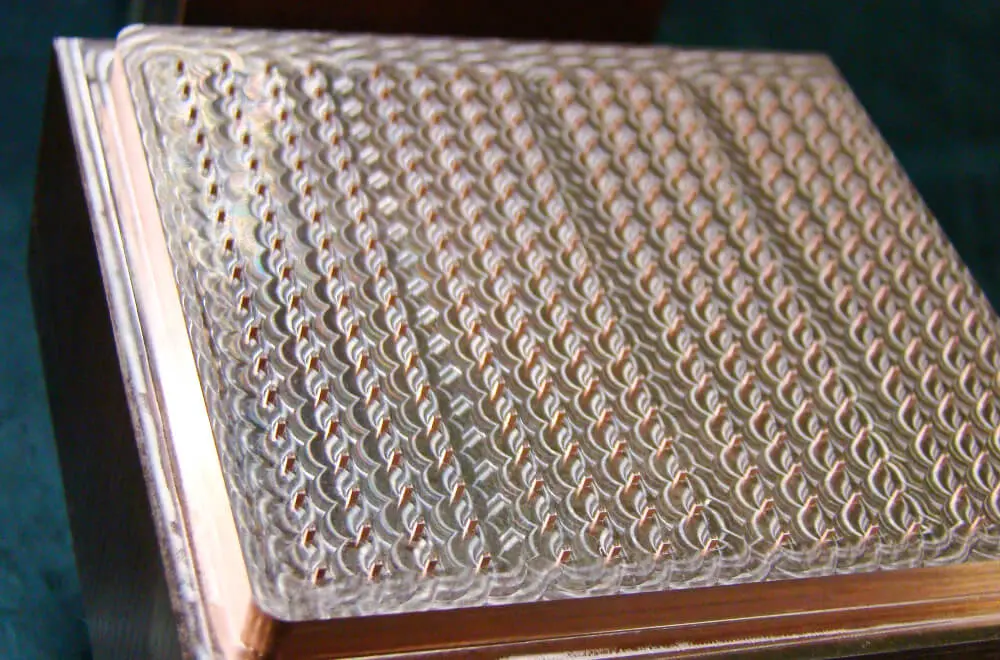

Advantage 1: Precision to Specifications

Custom plastic moldings allow you to exert precise control over the dimensions, shapes, and quality of your product, ensuring a perfect fit for your project’s unique demands. Whether you require micro-components, tight tolerance molding, or intricate parts, a professional manufacturer can customize your moldings to guarantee precision.

Advantage 2: Material Diversity

Advantage 3: Comprehensive Project Support

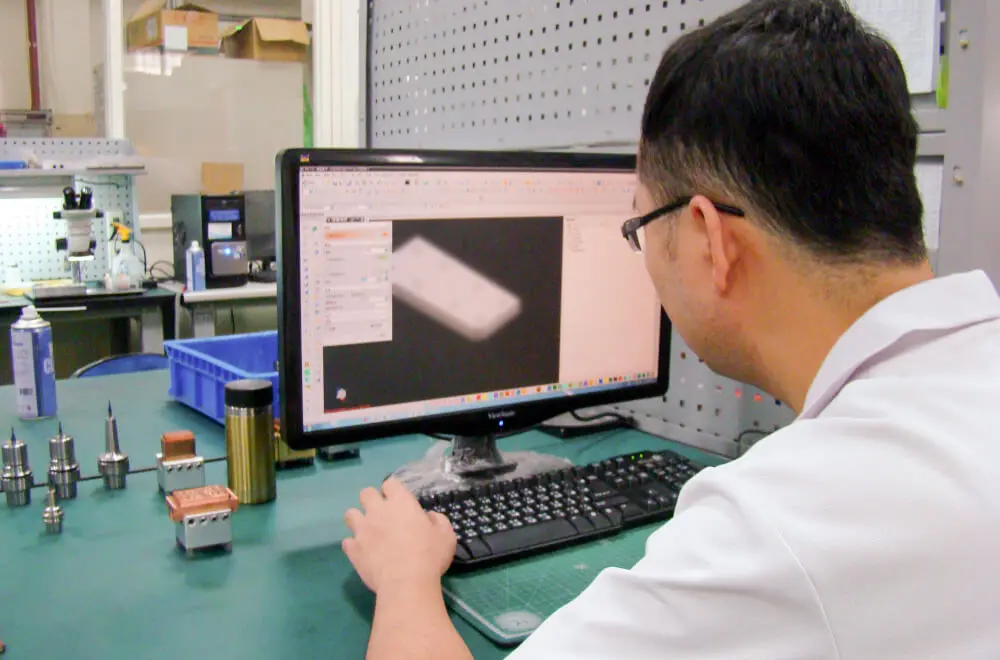

Custom plastic moldings involve more than just production; they encompass comprehensive project support from design to manufacturing. Expert manufacturers have experienced engineering teams that can assist you in designing and optimizing your parts, improving production efficiency, and reducing costs. THY provides services such as prototype development, mold design, and post-processing, ensuring your project receives full support.

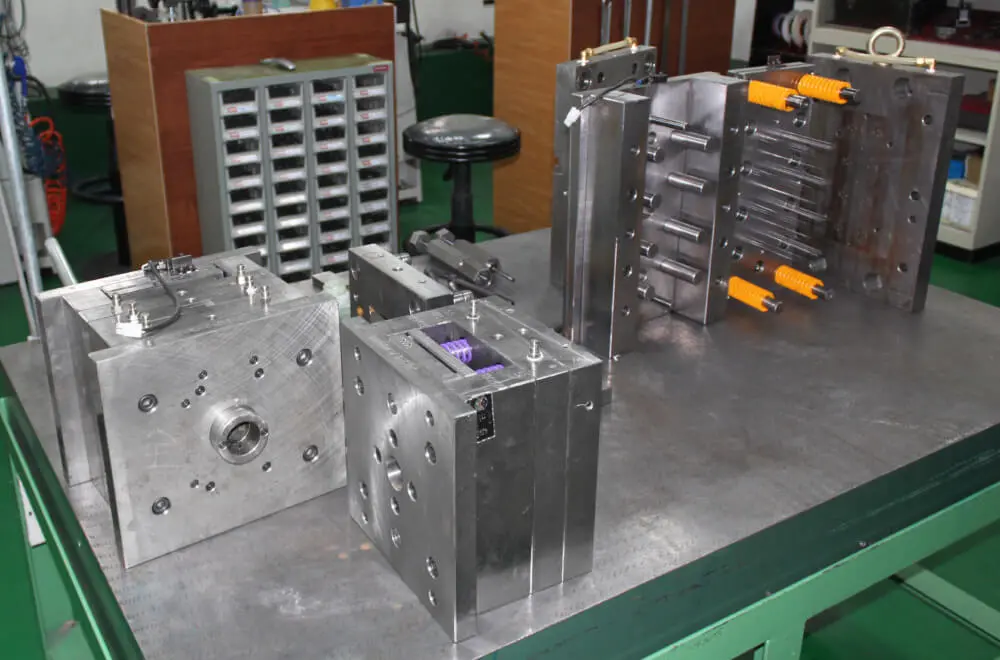

THY Precision's Capabilities in Custom Plastic Moldings

THY Precision is a professional high-precision plastic injection molding manufacturer with years of experience and an outstanding reputation. Our commitment to providing customized solutions ensures that we meet the diverse needs of various industries. Our engineering team can collaborate closely with you to ensure your project meets the highest standards.

Contact us to learn how you can initiate your custom plastic molding project, and let us help you turn your vision into reality.

Injection Molding & Automation in Manufacturing

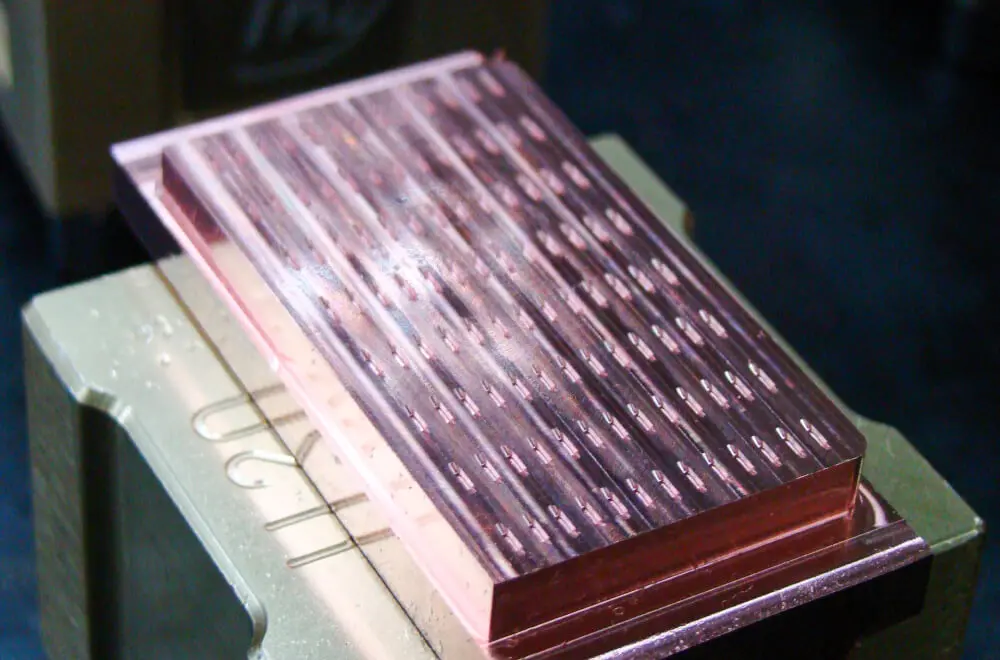

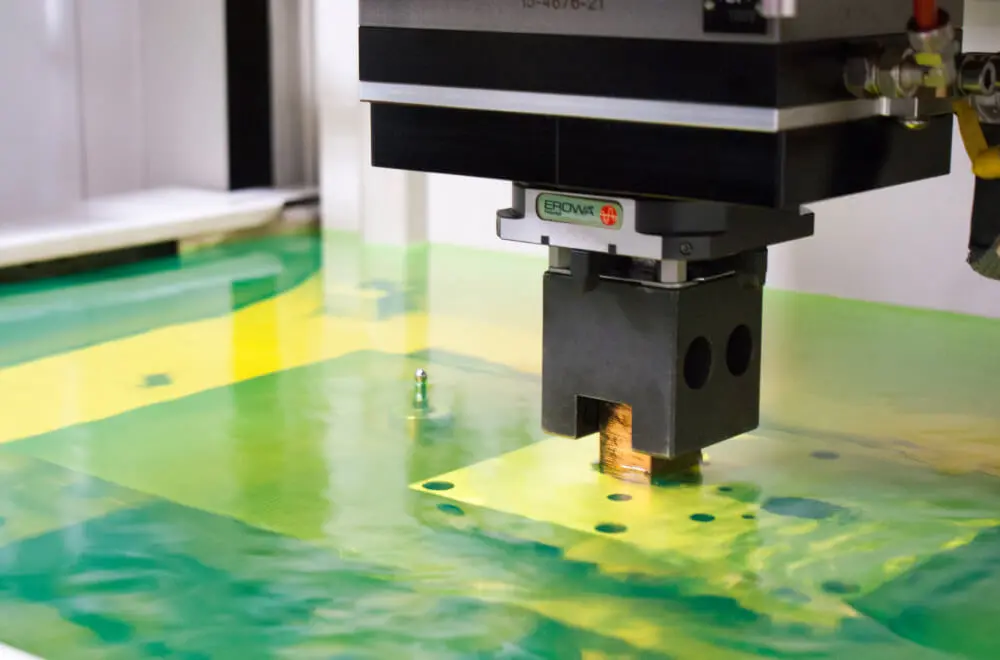

All-Electric Injection Molding Machines

At THY Precision, our commitment to innovation and sustainability is reflected in our state-of-the-art, all-electric servo-driven injection molding machinery. Unlike traditional hydraulic pump motor-driven machines, our all-electric models offer numerous benefits:

Cleanliness

Our all-electric machines are free from hydraulic oil, eliminating the risk of oil leaks and spills on the factory floor. This not only ensures a cleaner, safer workplace but also minimizes environmental impact.

Precision and Repeatability

We take pride in delivering the highest levels of precision and repeatability in the industry. With our all-electric technology, you can count on consistent, quality results every time.

High-Speed Molding

Our machinery is designed for high-speed molding, optimizing production efficiency without compromising on quality. You can trust us for swift and reliable output.

Automation and Accuracy

We offer automation features that enhance productivity and accuracy. With our all-electric injection molding machines, you can expect superior control and precision in every production run.

Choose THY Precision for a cleaner, greener, and more precise injection molding solution that sets industry standards.

Contact us to learn more about our cutting-edge technology.

Secondary Operation

Our specialization in custom plastic moldings extends beyond manufacturing. We offer a comprehensive suite of secondary and value-added services to enhance your product development process. Our services include:

Ultrasonic Welding

Achieve precision and durability through our ultrasonic welding techniques, enhancing the structural integrity of your custom plastic moldings.

Spray Paint and Coating

Elevate the look and protection of plastic components with spray paint or coating services, ensuring a lasting, high-quality finish.

Insert Installation

Whether through heat or ultrasonic methods, we excel in the seamless installation of inserts to optimize the functionality of your custom plastic moldings.

Component Assembly

Our expert team is skilled in assembling both molded components and externally sourced parts, delivering a ready-to-market solution.

Pad Printing

Elevate your branding and labeling with our pad printing services, making your custom plastic moldings stand out.

Laser Engraving

For precision marking and customization, we provide laser engraving to meet your unique specifications.

Functional Testing

We conduct rigorous functional testing to ensure that your custom plastic moldings meet the highest quality standards.

Packaging Design and Development

Our packaging solutions are tailored to protect and showcase your custom plastic moldings effectively.

Our commitment is to deliver the most cost-effective solutions possible, all while focusing on your specific custom plastic moldings needs. Contact us today to explore how our extensive services can enhance your manufacturing processes and product development.