HOME / Optics

Lens and Optical Injection Molding Company

Optical Plastic Injection Molding Services with Global Quality Standards

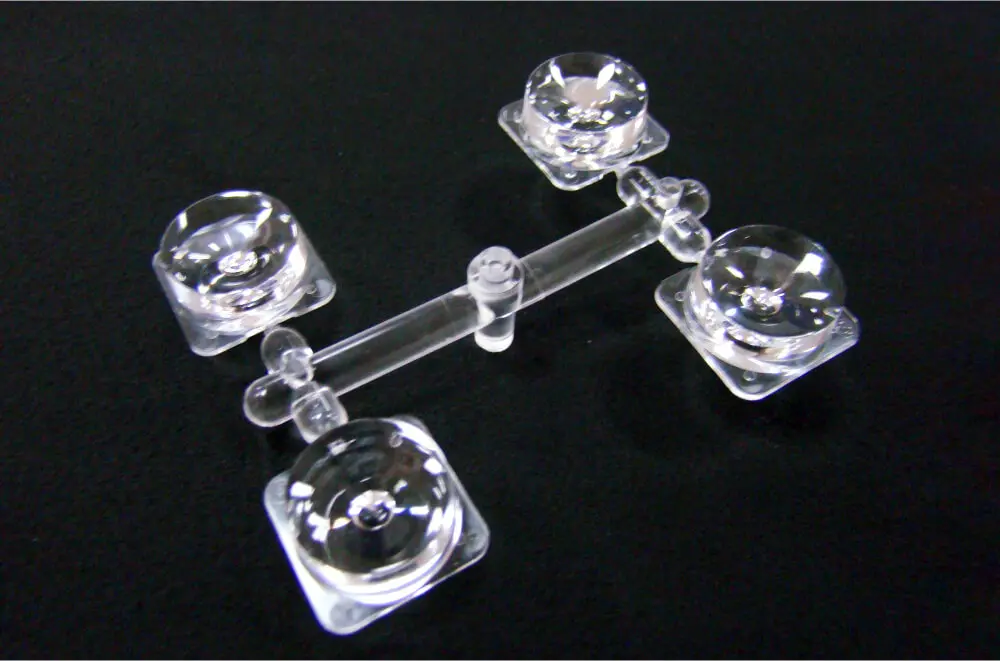

THY Precision is a leading provider of optical injection molding services for plastic components that meet international quality standards. We specialize in producing TV LED light beams, lens holders, lens barrels, lens spacers, lens retainers, lens hoods, optical mouse lenses, and transparent parts, among others.

One of our key strengths is our advanced ultra-precision CNC diamond turning lathe, the Nanotech 250 UPL. This state-of-the-art machine allows us to produce spherical and aspheric optical lenses, mirrors, mold inserts, freeform optics, and mechanical components with sub-nanometer level surface finishes and sub-micron accuracies. We work with a wide range of materials to provide our clients with the best possible custom plastic molding solutions for their ultra-precision applications,

- Geometric dimension less than 0.5μm

- Surface finish less than Ra 0.5nm

Micro-optics on non-flat substrates

Contact lenses plastic mold manufacturing

Optical fibers

Optical components

Diffractive optical elements

Optical Plastic Injection Molding Manufacturer

As a leader in the field of optical injection molding, THY Precision excels in both lens molding and optical molding. Our unwavering commitment to the highest quality and precision benchmarks in the optical component manufacturing sector ensures that the products we deliver, from sophisticated lens moldings to advanced optical moldings, are of the utmost efficacy and reliability. If you require unparalleled precision in optical components, contact THY Precision to explore how we can meet your needs.

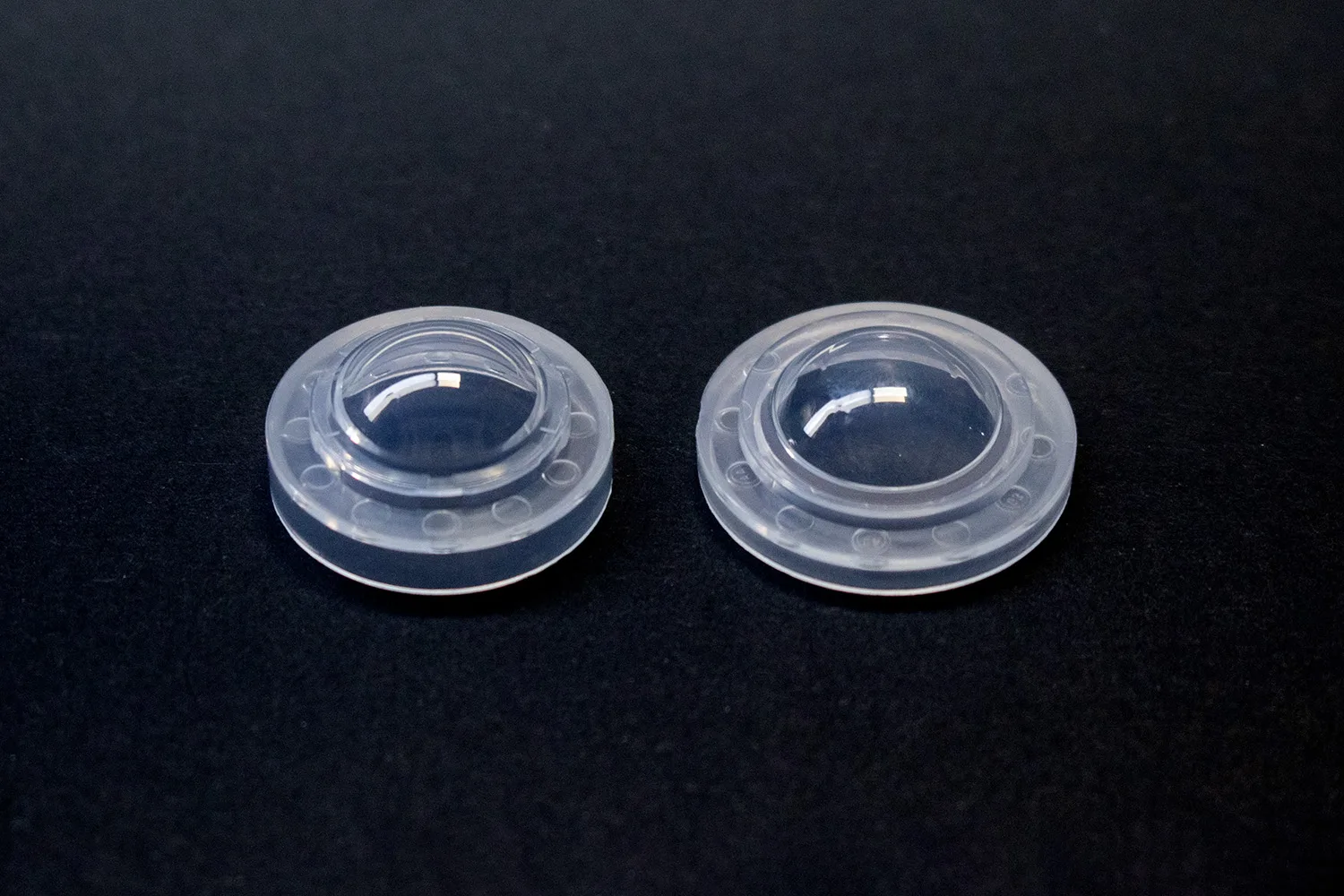

Contact Lenses Plastic Mold Manufacturing

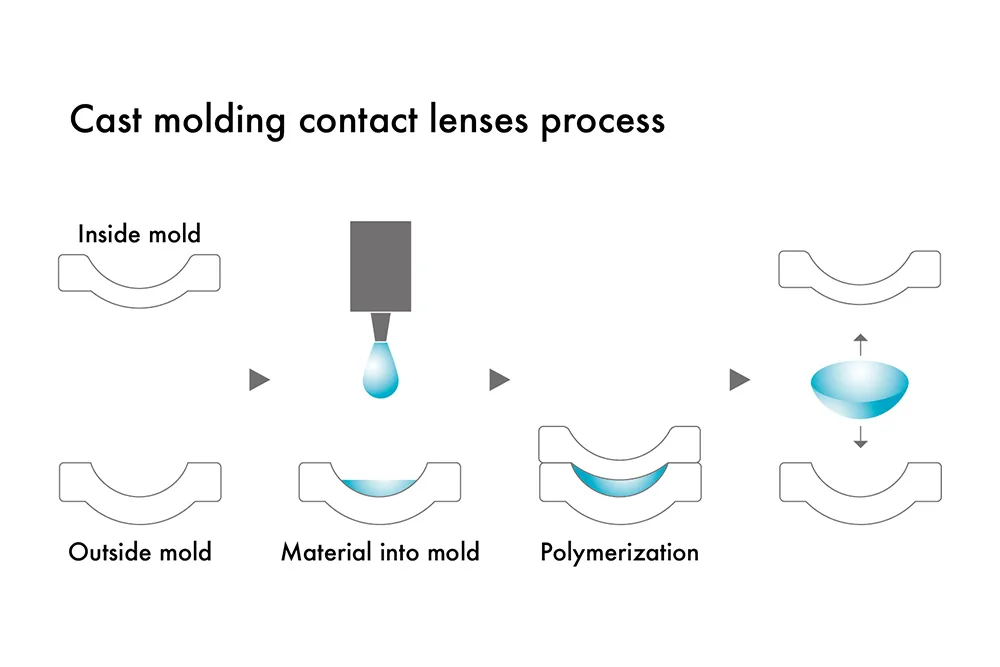

THY Precision manufactures contact lens molds using advanced all-electric injection molding machines to ensure exceptional repeatability, precision, and compliance with ISO Class 8 cleanroom standards. High repeatability is a critical requirement in lens mold production, enabling consistent quality while supporting high-volume, cost-efficient manufacturing.

For manufacturers specializing in contact lens mold production, the ability to reproduce molds with ultra-high accuracy on a continuous basis is essential. THY Precision’s manufacturing approach ensures tight tolerances and reliable performance across every production cycle, supporting scalable mass production without compromising quality.

Automation plays an equally vital role in maintaining cleanroom integrity and production efficiency. Each lens mold is typically produced with robotic systems handling critical tasks such as automated demolding, tool unloading, and packing into sterile carriers. This high level of automation minimizes human contact, enhances cleanliness, and ensures consistent output in medical-grade lens mold manufacturing.

Plastic Injection Molds for Silicone Hydrogel Contact Lens

THY Precision specializes in high-precision contact lenses plastic molds designed for medical-grade and silicone hydrogel contact lens manufacturing. Our contact lens injection molds are engineered with ultra-precision machining, mirror polishing, and high repeatability to ensure consistent optical quality. All molds are produced under ISO 13485 certified quality systems and supported by cleanroom injection molding capabilities.

High-Precision Contact Lens Mold Manufacturing in ISO Class 8 Cleanroom