HOME / Medical Device Injection Molder/Molding Company

Medical Device Injection Molder/Molding Company

With years of experience in medical device injection molding, THY Precision delivers high-quality custom injection solutions to the global medical industry. As one of the leading medical device injection molding companies, we are dedicated to helping our clients produce medical products that meet strict quality and safety standards.

Service Scope of Medical Device Injection Molding Companies

Our medical device injection molding services cover a wide range of applications, including but not limited to:

• Medical Filtration and Implantable Components:

Including chamber filters, dialyzer filters, caps, and medical-grade implantable plastic components.

• Intravenous and Infusion Components:

Such as pump connectors, intravenous infusion drip components, and bacteria filters.

• Medical and Laboratory Consumables:

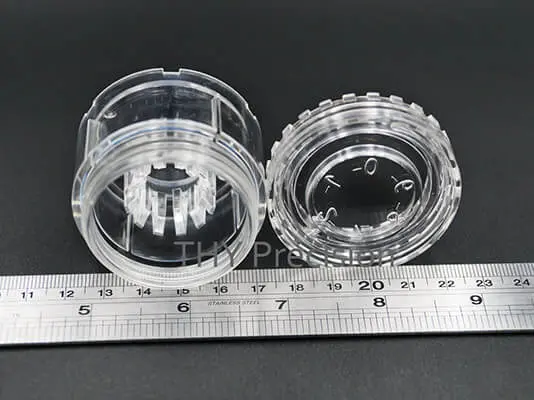

Including plastic components for blood bags, laboratory consumables, cartridges and injectors for IOL (Intraocular lens) applications.

Technological Capabilities of Medical Injection Molders

At THY Precision, we employ state-of-the-art medical plastic components and injection molding technology to ensure the highest levels of precision and reliability. Our technological capabilities include:

• Advanced Injection Molding Machines:

Over 80 machines ranging from 30-ton to 300-ton presses, capable of producing millions of units monthly with real-time monitoring for consistent quality.

• Cleanroom Manufacturing:

Our ISO certified medical molding includes an ISO Class 8 cleanroom for molding and an ISO Class 7 cleanroom for assembly, ensuring sterile, contaminant-free production and packaging of medical devices.

• Material Expertise:

We assist you in selecting from a variety of medical-grade plastics and elastomers, providing guidance based on your specific application needs and employing best practices to ensure your product’s successful market entry.

Quality Assurance

Quality is at the core of everything we do. Our quality assurance processes include:

• Rigorous Testing and Validation:

All products undergo thorough testing and validation to ensure they meet industry standards and customer specifications.

• Clean Room Molding and Assembly:

At THY Precision, we prioritize precision and quality in the medical device industry. Our highly skilled team uses specialized facilities and techniques to produce accurate plastic medical devices. We are committed to the highest industry standards, including ISO 13485 certification, ensuring our manufacturing processes meet stringent medical device quality management requirements.

• Continuous Improvement:

We utilize advanced automated inspection technologies, including AOI and intelligent image recognition, to enhance precision, reduce defects, and ensure high-quality, efficient services.

Comprehensive Medical Device Manufacturing Services

At THY Precision, we offer a wide range of specialized services to meet the needs of the medical device industry. Our expertise and state-of-the-art facilities ensure the highest quality products and solutions for our clients. Our services include:

Disposable Medical Consumables and Laboratory Supplies

Medical Grade Plastic Injection Molded Components

Medical Device Assembly and Packing System

Durability and Biocompatibility

ISO Class 8 (100K) CleanRoom for Molding & ISO Class 7 (10K) Cleanroom for Assembly

THY Precision: A Front-Runner Among Medical Injection Molders

The medical device injection molding industry plays a crucial role in the production of medical equipment that meets the increasing global demand for healthcare solutions. Market trends show a growing emphasis on precision and efficiency, with innovations in cleanroom technology and automated production processes enhancing the quality and consistency of medical components. The industry also faces challenges such as maintaining compliance with evolving regulatory standards and ensuring the scalability of production to meet diverse client needs.

At THY Precision, we leverage our extensive industry experience and cutting-edge technologies to address these trends and challenges, providing our clients with exceptional service and top-tier medical device components.

As one of the leading medical device injection molding companies, THY Precision stands as a trusted choice among medical injection molders. We are dedicated to upholding the highest quality and precision standards in the medical device manufacturing industry, ensuring the safety and efficacy of the devices we produce.

If you are interested in medical device injection molding and require top-tier quality and precision, we invite you to contact THY Precision to discuss how we can meet your specific needs.

THY Precision provides customized medical plastic injection molding services.